Showing posts with label BUILDING MATERIAL. Show all posts

Showing posts with label BUILDING MATERIAL. Show all posts

Thursday 23 October 2014

Sunday 17 August 2014

LOS ANGELES ABRASION TEST , HOW and WHY TO PERFORM

LOS ANGELES

ABRASION TEST:

This is hardness test for aggregates, used in Laboratory to determine the hardness value or abrasion value

APPARATUS :

Los Angeles Abrasion Testing Machine ,

Abrasive

Charge – Cast iron or steel balls ,

Test sieve – 1.70 mm IS sieve ,

Test sieve – 1.70 mm IS sieve ,

Balance of capacity 10 kg , Oven , Tray

The aggregate used in surface course of the highway pavements are

subjected to wearing due to movement of traffic.

When vehicles move on the road, the soil particles present between the pneumatic tyres and road surface cause abrasion of road aggregates.

The steel reamed wheels of animal driven vehicles also cause considerable abrasion of the road surface.

Therefore, the road aggregates should be hard enough to resist abrasion.

The principle of Los Angeles abrasion test is to produce abrasive action by use of standard steel balls which when mixed with aggregates and rotated in a drum for specific number of revolutions also causes impact on aggregates.

The percentage wear of the aggregates due to rubbing with steel balls is determined and is known as Los Angeles Abrasion Value.

When vehicles move on the road, the soil particles present between the pneumatic tyres and road surface cause abrasion of road aggregates.

The steel reamed wheels of animal driven vehicles also cause considerable abrasion of the road surface.

Therefore, the road aggregates should be hard enough to resist abrasion.

The principle of Los Angeles abrasion test is to produce abrasive action by use of standard steel balls which when mixed with aggregates and rotated in a drum for specific number of revolutions also causes impact on aggregates.

The percentage wear of the aggregates due to rubbing with steel balls is determined and is known as Los Angeles Abrasion Value.

Key point of los angles test:

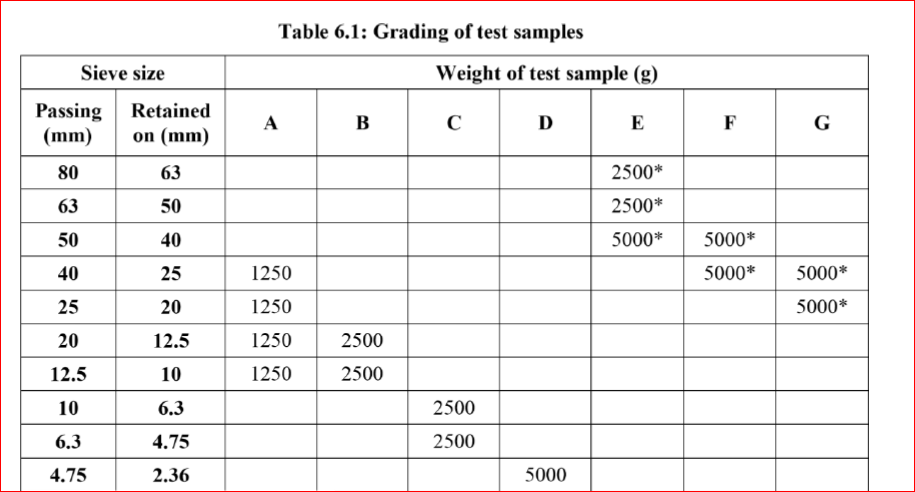

Rotate the

machine at a speed of 30 – 33 revolutions per minute. The number of revolutions

is 500 for grading A, B, C & D and 1000 for grading E, F & G. The

machine should be

5 kg of

sample for grading A, B, C & D and 10 kg for grading E, F & G

THE

CALCULATION PART:

Original

weight of aggregate sample = W1 g

Weight of

aggregate sample retained = W2 g

Weight

passing 1.7mm IS sieve = W1 - W2 g

Los Angeles Abrasion Value = (W1 - W2) / W1 X 100

Los angeles abrasion value should lies in below given range for different types of roads

Types of pavement layers Max. Permissible Abrasion Value in %

1:WBM , SUB BASE COURSE 60%

2:WBM BASE COURSE WITH BITUMEN SURFACE 50%

3: BITUMEN BOUND MACADAM 50%

4:WBM SURFACING COURSE 40%

5: BITUMINOUS PENETRATION MACADAM 40%

6:BITUMINOUS SURFACING DRESSING CEMENT

CONCRETE SURFACING COURSE 35%

7:BITUMINOUS CONCRETE SURFACING COURSE 30%

Monday 28 October 2013

Test for Bricks:

A brick is taken and it is weighed dry. It is then immersed in water for a period of 16 hours. It is weighed again and the difference in weight indicates the amount of water absorbed by the brick. It should not in exceed 20 per cent of weight of dry brick.

(2) Compressive/Crushing strength of Bricks:

The crushing strength of a brick is found out by placing it in a compression testing machine. It is pressed till it breaks. the minimum crushing or compressive strength of bricks is 3.50 N/mm2.

The bricks with crushing strength in between of 7 N/mm2 to 14 N/mm2 are graded as A and those having above 14 N/mm2 are graded as AA,

(3) Hardness test on bricks:

In this test, a scratch is made on brick surface with the help of a finger nail. If no impression is left on the surface, the brick is r sufficiently hard.

(4) Presence of soluble salts:

The soluble salts, if present in cause efflorescence on the surface of bricks. For finding out the presence of soluble salts in a brick, it is immersed in water for 24 hours. It is then taken out and allowed to dry in shade. The absence of grey or white deposits on indicates absence of soluble salts.

If the white deposits cover about 10 per cent surface, the efflorescence is said to be slight and it is considered as moderate, when the white deposits cover about 50 per cent of surface. If grey or white deposits are found on more than 50 per cent of surface, the efflorescence becomes heavy and it is treated as serious, when such deposits are converted into powdery mass.

(5) Shape and size:

In this test, a brick is closely inspected. It should be of standard size and its shape should be truly rectangular with sharp edges. For this purpose, 20 bricks of standard size (190 mm x 90 mm x 90 mm) are selected at random and they are stacked lengthwise, along the width and along the height.

(6) Soundness test on brick:

In this test, the two bricks are taken and they are struck with each other.

The bricks should not break and a clear ringing sound should be produced.

The bricks should not break and a clear ringing sound should be produced.

Other test can be perform but these 6 are the important once.

Tuesday 30 April 2013

==>>COMPRESSIVE STRENGTH TEST FOR CONCRETE==>>

AIM==>>

To determine the compressive strength of concrete cylinders.

APPARATUS==>>

Compression testing machine, cylinder mould of 150mm diameter and 300mm height, weighing balance.

PROCEDURE==>>

=>Cast the cylinder and cure for 28 days.

=>Takeout the specimen from the curing tank.

=>Wipe out the excess water from the surface of specimen.

=>Place the specimen vertically on the platform of compression testing machine.

=>Apply the load continuously and uniformly without shock at the rate of 315 kn/min. And continue the loading until the specimen fails.

=>Record the maximum load taken.

CALCULATIONS==>>

Range Calculation

Characteristic compressive strength at 28 days = N/ mm2

Area of cross section = (PI/4)*D^2

Expected load = stress x area

COMPRESSIVE STRENGTH==>>

Compressive strength = Maximum load/ Cross sectional area

RESULT==>>

Compressive strength of cylinder =…………………….N/mm2

Saturday 20 April 2013

==>>DEFECTS IN CONCRETE==>>

==>>DEFECTS IN CONCRETE==>>

EFFLORESCENCE ==>> Is the appearance of fluffy white patches on the surface of concrete members. It

is caused by poorly washed aggregate, salty water used in making concrete the salts being leaching out to the surface by rain water afterwards. As the water evaporates white patches appear on the surface. This defect can be controlled to some extent by coating the surface by a water repellent.

SEGREGATION==>>

usually implies separation of: =>1 coarse aggregate from fine aggregate, =>2 paste from coarse aggregate, or water from the mix and the ingredients of the fresh concrete no longer remain uniformly distributed. It can be reduced by increasing small size coarse aggregate, air entrainment, using dispersing agents and puzzolana.The causes of segregation are dropping concrete from heights, badly designed mixes, concrete carried over long distances—pumping, belt conveyor system etc. over vibrations, and during concrete finishing extra floating and tamping.Segregation mainly occurs in dry non-sticky concrete mixes.

CRAZING ==>>

of concrete products results from differences in shrinkage between the surface and the interior. The cracks rarely exceed 12 mm or so in depth, and are therefore not serious, apart from the unsightliness. The best method to overcome crazing is to be either to use an earthmoist mix, or if a plastic mix is necessary use as low a w/c ratio as is practicable and remove the cement skin to expose the aggregate. Trowelling should be avoided, as the surfaces are prone to crazing.

BLEEDING==>>

defined as an autogeneous flow of mixing water within or emergence to the surface from freshly placed concrete is usually due to excessive vibrations imparted to concrete to achieve full compaction. However well concrete may have been compacted, the force of gravity.This upward migration of water known as bleeding ceases either when the solid particles touch each other and cannot settle any more, or when the concrete stiffens due to cement hydration and prevents further movement. It can be reduced by grinding cement fine, or by using air entraining agents, dispersing agents, puzzolanas and by imparting vibration. It is a

particular form of segregation in which some of the water comes out on the surface of concrete. Mixes which bleed excessively are those which are harsh and not sufficiently cohesive. Basically this is caused by the lack of very fine materials in mix. Obviously this is because of the coarse sand or when the sand content has been kept low. The causes of bleeding are highly wet mix, insufficient mixing, and thin sections (slabs) cast in sunny weather—being more in flaky aggregate and more in the first hours of concreting. The ill effects are reduced bond between aggregate and cement, and between cement and reinforcement.

Bleeding can be checked by the use of uniformly graded aggregates, puzzolana—by breaking the continuous water channel, or by using—entraining agents, finer cement, alkali cement, and a rich mix.

SULFATE ATTACK==>>

Sulphate attack is mainly caused by the soil containing sulphates or by sulphate water.

FACTOR AFFECTING WORKABILITY OF CONCRETE:

FACTOR AFFECTING WORKABILITY OF CONCRETE:

WATER CONTENT: The fluidity of concrete increases with water content. At site the normal practice is to increase the water content to make the concrete workable which lowers strength. In controlled concrete this cannot be resorted and even in uncontrolled concrete this should be the last choice. However, in case if more water is added due to any reason the cement content should be proportionately increased.

MIX PROPORTIONS:

Aggregate-cement ratio influences the workability to a large extent. The higher the ratio leaner will be the concrete. In a lean concrete, paste available for lubrication of per unit surface area of aggregates will be less and hence the workability is reduced.

AGGREGATE SIZE:

For big size aggregate the total surface area to be wetted is less, also less paste is required for lubricating the surface to reduce internal friction. For a given water content big size aggregate give high workability.

SHAPE OF AGGREGATE:

For a given water content, round and cubical shape aggregates are more workable than rough, angular or flaky aggregates, because the former type of aggregates requires less cement paste for lubrication as these have less surface area and lesser voids. In case of round aggregates frictional resistance is also small so less lubrication is required. For this reason river sand and gravel provide greater workability than crushed sand and aggregates.

SURFACE TEXTURE:

A rough surface aggregate will have more surface area than a smooth round textured aggregate. Hence, latter will be more workable for the reasons discussed above.

GRADING OF AGGREGATES:

Properly graded aggregates are more workable. It is so because such a mix will have least voids and thus excess cement paste will be available as lubricant. This also prevents segregation.

ADMIXTURES:

Air entrained concrete is more workable. It is so because air forms bubbles, on which the aggregates slide past each other increasing the workability. Another factor is that air entraining agents are surface active and they reduce the internal friction between the aggregates.

.jpg)